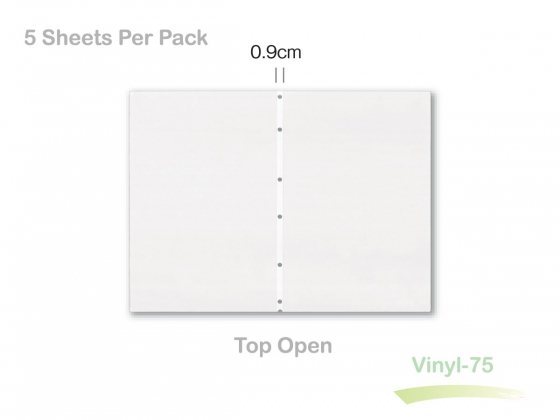

Vinyl-75 Clear Sleeve

Our high-quality vinyl sleeve use environmentally safe and toxic free P.P with heavy-duty 0.15mm thickness. Special non-stick formulate to ensure your printing content will not back print on the sleeve. 5 sheets per pack.

Our high-quality vinyl sleeve use environmentally safe and toxic free P.P with heavy-duty 0.15mm thickness. Special non-stick formulate to ensure your printing content will not back print on the sleeve. 5 sheets per pack.

1th June 2020

5th January 2018

1th December 2017

4th November 2017

![]()

Copyright © ORSTON All Rights Reserved. ABN: 38 604 900 209. Website by Imagine If Media

By uploading your artwork with Orston Pty Ltd here you are agreeing to following terms and conditions:

a) Once you upload your artwork for your order this is final. If there are any issues with your artwork we will notify you first, otherwise printing will begin from the file you supply.

b) If the artwork supplied does not satisfy the criteria on the print template we will contact you and there will be a 'resubmission fee' outlined below.

c) If you choose to change your artwork and we have not yet begun the printing process there will be a 'resubmission fee' outlined below.

Resubmission Fee: For each resubmission there is a $55 inc. GST fee. This is payable via invoice before we recommence your job.

Contact us here if you have any questions.

We can print your company logo or custom design on your menu covers. This adds a unique aesthetic and helps branding your establishment. The per unit fees for each style of printing are outlined next to each print option in the select list. There is no additional discount for custom printing like there is on the covers themselves.

This is a high quality full colour print using a UV process. There are no additional setup fees for this option. If you require a larger print size than 10cm x 10cm there will be additional fees for this. Contact us here for a quote.

This process places a foil stamp in the colour of your choice. If you require a larger print size than 15cm x 15cm there will be additional fees for this. Contact us here for a quote.

All custom printed items require an artwork file to be supplied for each order. After you checkout you will be prompted to upload this file.

Click here to download printing design template.

Click here if you would like us to help you design your art.

Click here to contact us if you have any questions.

When we do Foil Stamping we first need to create your copper plate stamp master. Due to the complexity involved in this we charge a one-off $105 (inc GST) for creating the plate for the first order and then $40(nc GST) for every order after that

Click here to contact us if you have any questions.

When we do stamp printing we need to first create a copper plate and then setup your job. Because of the process involved we charge additional fees for this printing option outlined below.

Option 1. Copper plate creation + setup fees for new customers - $105 (inc GST)

This option is required if you have NOT done done stamp printing with us before - or - you wish to change your logo or design from your last stamp print job. This fee covers creation of your copper plate + setup for the new job. After we make your copper plate (provided your designs do not change) you can use this for your next stamp printing job with us and only pay the reduced rate for setup fees below.

Option 2. Setup fees for existing customers who already have a copper plate - $40 (inc GST)

This is option is only for customers who we have previously made a copper plate for your last stamp printing job and the design or logo has not changed. This fee covers setting up your new job and using your existing your existing plate.

Q: If I order more than 1 type of product with stamp printing do I need to pay additional plate or setup fees for each item?

A: No, not unless you wish for a different design to be on the different items. If these are different you will need to purchase a new plate for each job.

Q: I have a copper plate made by another company, can I use this?

A: Unfortunately not because we use a unique process for our machinery and therefore need to make a new plate